Why we are the most dedicated Drilling Team

We’ve dumped all of our resources into perfecting our services by developing techniques no one else provides at a quality no one else can match.

Our Quality Markers

98% Mechanical Uptime

98% Mechanical Uptime

The benefit of manufacturing our own drill rigs is that we have very precise control over the quality of our equipment and an intimate understanding of its operation and capabilities. Our high-quality manufacturing and superior maintenance practices have allowed us to maintain a mechanical uptime above 98%. Rest assured that you don’t need to wait on malfunctions or overheats to progress your operation. While we are on the job site, the drill is always ready to go. Our reliability means less complications and faster project completion.

No LTA’s in over 12 years

No LTA’s in over 12 years

We take safety very seriously. Through the use of our central communication team, we keep constant watch over each employees’ biometrics to avoid over exertion or injury. Our project management team keeps a close eye on the operation of the drill at all times to ensure all equipment is being operated safely and efficiently. Our advanced training, practices, and external monitoring we means that we have maintained a perfect record of no lost time accidents in over 12 years of operation.

No Lost holes in over 7 years

No Lost holes in over 7 years

We are no strangers to drilling difficult land, from ice to clay, granite to gold. Yet our in-depth understanding of geology and drilling mechanics mean we have achieved 100% hole completion with no lost holes in over 7 years. Our team is given intense training to understand how to properly regulate water pressure, heat, and drill speed to ensure hole failure is an impossibility on our job sites. Our expertise means that you can reliably reach each target you plan for and more accurately budget the development of your project.

Capabilities

Positive Angle Surface Drilling

We custom make all of our drill rigs, which allows us to augment our equipment to perform specialized functions that we haven’t been able to find anywhere else in the industry. For example, our surface rigs can drill at a positive angle, allowing us dig through

the soft topsoil of a hill or even a cliffside without risking hole loss. It allows our clients to stop thinking of the deposit in two dimensions and view it as a three-dimensional target that we can hit from the side, which has significantly sped up the discovery process on some of our projects.

the soft topsoil of a hill or even a cliffside without risking hole loss. It allows our clients to stop thinking of the deposit in two dimensions and view it as a three-dimensional target that we can hit from the side, which has significantly sped up the discovery process on some of our projects.

Silverless Drill Bits

Precision matters when working in mineral discovery. We know how important it is to avoid contamination of core samples, which is why we use and sell Silver-less drill bits exclusively. Most diamond core drill bits use silver composite as a binding agent.

As the bit is worn away that silver can mix with the sample and provide false positives for mineralization. To ensure your discovery is as accurate as possible, we partnered with LazerBit to produce a drill bit that doesn’t contain any silver, copper, or pewter composites.

As the bit is worn away that silver can mix with the sample and provide false positives for mineralization. To ensure your discovery is as accurate as possible, we partnered with LazerBit to produce a drill bit that doesn’t contain any silver, copper, or pewter composites.

Gondola Drill Mobilization

Most remote access drillers use man-portable rigs that are dangerous to move and have limited depth, or helicopter lifts that are expensive and difficult to re-locate. Instead, we have developed our own methods and technology to efficiently set up full-sized drills in the most remote locations.

By a system of winches, pulleys, and an aerial gondola sled, we are able to traverse steep cliffs, valleys, and dense forests without road access. This technique allows us to access the most remote locations faster and safer than any of our competitors.

By a system of winches, pulleys, and an aerial gondola sled, we are able to traverse steep cliffs, valleys, and dense forests without road access. This technique allows us to access the most remote locations faster and safer than any of our competitors.

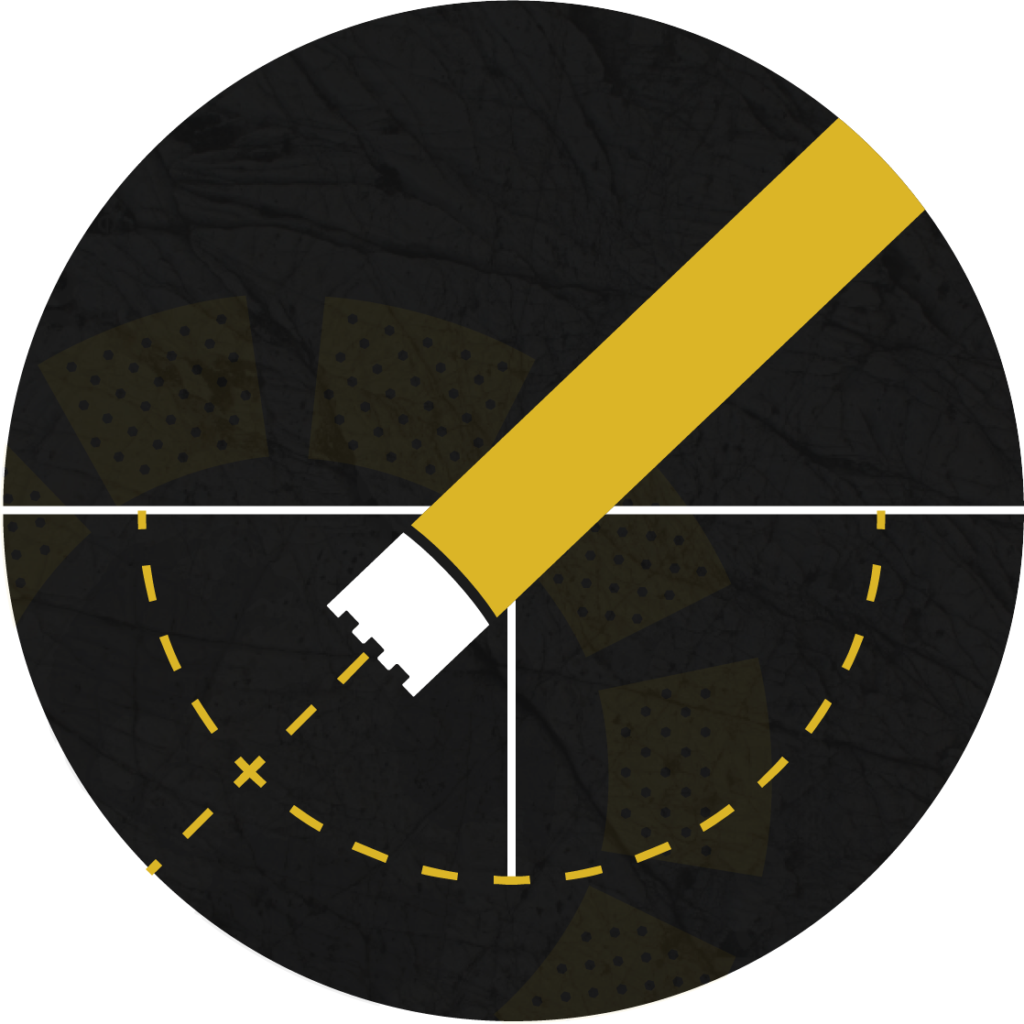

Advanced Precision Drill Trajectories

Over the years we have gained an intimate understanding of our equipment and the deviations we can expect from certain types of terrain. By anticipating these deviations, we can accurately and reliably reach your target even in less-than-ideal conditions.

Our capabilities even allow us to purposefully curve our holes to reach difficult to access targets without sacrificing the accuracy of our depth reports.

Our capabilities even allow us to purposefully curve our holes to reach difficult to access targets without sacrificing the accuracy of our depth reports.

Continuous Accuracy Hole Mapping

Industry standard drill rigs measure the angle of the hole at set intervals to calculate its trajectory. This method leaves much room for error as it doesn’t account for the arc of the hole’s curve. Our testing shows that incrementally measuring azimuth in this way can

lead to hole mapping that is off by more than 50 meters at the target. To reduce this inaccuracy, we continually calculate the curve of our drill holes to precisely map each hole in three dimensions with a very low margin of error.

lead to hole mapping that is off by more than 50 meters at the target. To reduce this inaccuracy, we continually calculate the curve of our drill holes to precisely map each hole in three dimensions with a very low margin of error.

Core Care Recovery

We have always prided ourselves on the ability to get the best results from the worst ground. Sometimes you need to drill through 100 meters of clay to reach the deposit you are looking for, and we recognize the importance of properly cataloguing every inch of

your sample. That is why we work to provide unmatched core recovery care. Our samples are instantly documented for review, accurately measured according to your preference, and reverently protected. We even offer core alignment services to ensure you have the most reliable data possible to inform your discovery. Our dedication to your recovery is why our clients all say we provide the cleanest core and best recovery they’ve ever had.

your sample. That is why we work to provide unmatched core recovery care. Our samples are instantly documented for review, accurately measured according to your preference, and reverently protected. We even offer core alignment services to ensure you have the most reliable data possible to inform your discovery. Our dedication to your recovery is why our clients all say we provide the cleanest core and best recovery they’ve ever had.

Let´s explore together

Unlock the potential beneath your feet. Schedule a consultation with our mining exploration experts to discuss your project’s needs and how our cutting-edge solutions can help you achieve your goals.

Schedule a meeting

We’d love to hear about your specific operation or tell you more about the things we can do that no one else can. Click below to schedule a meeting.